Have you ever wondered what exactly a thru hull fitting is on a boat and why it’s so crucial to marine operations? This seemingly simple component plays an integral role in the functionality and safety of vessels. Understanding its purpose and intricacies can significantly enhance your boating experience. Before delving deeper, consider this: what if your boat begins taking on water due to a faulty thru hull fitting? Not a pleasant scenario, right? Let’s explore what a thru hull fitting is, how it works, and why it deserves your attention.

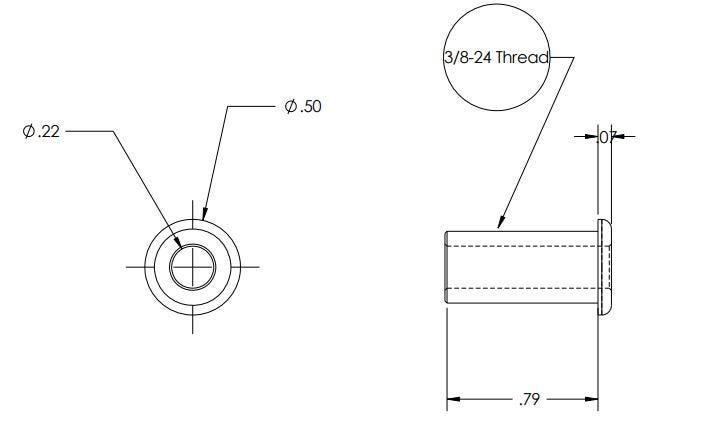

At its core, a thru hull fitting is a component installed in the hull of a boat allowing for the passage of fluids—be it water, fuel, or waste—between the outside environment and the interior of the vessel. This connection is vital for various systems, including cooling systems for engines, drainage of bilge water, and plumbing for onboard sinks and toilets. The design typically features a pipe-like structure that extends through the hull and is equipped with a seacock or valve to control the flow.

One of the most remarkable aspects of a thru hull fitting is its engineering. It often consists of durable materials like bronze, plastic, or stainless steel designed to withstand harsh marine environments. Marine life, corrosion, and wear can quickly degrade inferior materials, making the choice of material critical. For instance, bronze is favored for its longevity, offering resistance to corrosion and barnacle growth. However, it’s imperative to understand that each type of material comes with its own set of pros and cons. Knowledge of these nuances is essential for anyone eager to maintain their vessel effectively.

Now, let’s ponder a question many boaters may overlook: how does a thru hull fitting stay watertight? The answer lies in meticulous installation and maintenance practices. Proper sealing with marine-grade sealants during installation is non-negotiable. If not executed properly, the risks of leaks—potentially catastrophic failures—significantly increase. Given that the hull is the first line of defense against the ravages of water, ensuring that each fitting remains snug without any gaps is paramount.

Furthermore, the placement of these fittings is equally vital. Strategic positioning can offer advantages, such as allowing for better water flow and minimizing the risk of clogging. However, placing a fitting in a low-lying area can lead to accumulation of debris and marine growth, thus obstructing the system. Boaters should be vigilant and tasked with assessing whether their existing installations have been placed optimally. Regular inspections can flag issues before they turn into daunting challenges.

But what happens if your thru hull fitting starts to fail? Signs of trouble can range from minor leaks to loud gurgling noises indicating air locks within. Such issues can escalate rapidly and may necessitate immediate intervention. Boaters need to cultivate a mindset of proactive maintenance. Regularly checking for signs of wear and tear or corrosion can save you from distressing scenarios down the line.

Addressing a broken fitting often requires either repair or replacement. If you sense a compromised fitting, it is crucial to shut the corresponding seacock valve as soon as possible to prevent further flooding. This mitigation action is vital while you assess the damage. Depending on the severity, you may be able to tighten a loose fitting or, in more extreme cases, replace the entire component.

Replacement involves several steps. The first is to remove the old fitting, typically requiring tools like wrenches and possibly saws for stubborn components. After extraction, you will need to clean the surrounding area meticulously to ensure a proper seal when installing the new fitting. This process cannot be rushed; hasty actions may lead to future leaks. Once replaced, double-check all fittings and valves are secure and functioning properly.

For the more adventurous spirits, there are additional complexities regarding how your boat’s existing systems interplay with thru hull fittings. Most boats incorporate several systems reliant on various thru hull configurations. For example, consider cooling systems, which often utilize these fittings to draw water necessary to cool down engines. Understanding the intricacies of these systems adds another layer to the boating experience, increasing appreciation for the engineering marvels of your vessel.

Let’s not forget about regulatory considerations. Different regions have rules regarding the types of materials and fittings permissible on vessels for environmental protection. Compliance is essential not only to maintain your vessel but also to preserve marine ecosystems. If you’re operating in a particularly eco-sensitive area, ensure your thru hull fittings meet local standards. Neglecting these guidelines can lead to significant penalties and harm to local wildlife.

In conclusion, the thru hull fitting might seem like a mere accessory to your boat, yet it is fundamentally important in ensuring seafaring safety and efficiency. Engaging with this component involves understanding its various functions, proper maintenance practices, and potential risks. So, the next time you’re on your boat, take a moment to appreciate those little fittings holding the water at bay. Recognizing their significance could be the difference between a pleasurable excursion and a troublesome disaster.